Some people may believe that thicker is always better but whether it needs that added strength actually depends on the type of building construction as well as its location.

Purlin spacing for 29 gauge metal roofing.

An engineer will use a load chart in order to determine the spacing between metal purlins.

22 24 26 29 when it comes to metal roofing gauges thicker typically means that the cost will be higher.

We do recommend it however.

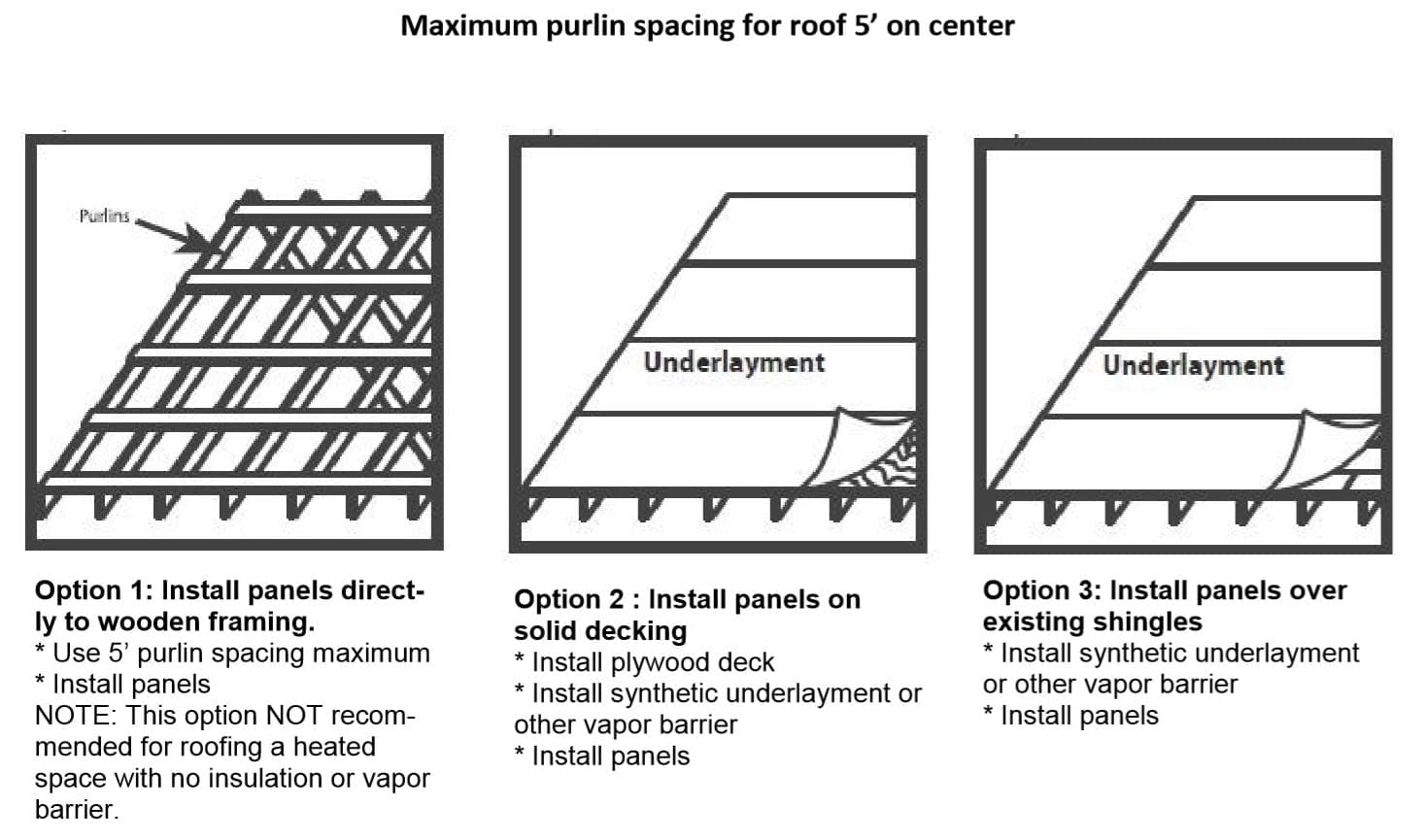

This will depend upon the type of panel that is used and the thickness of the steel.

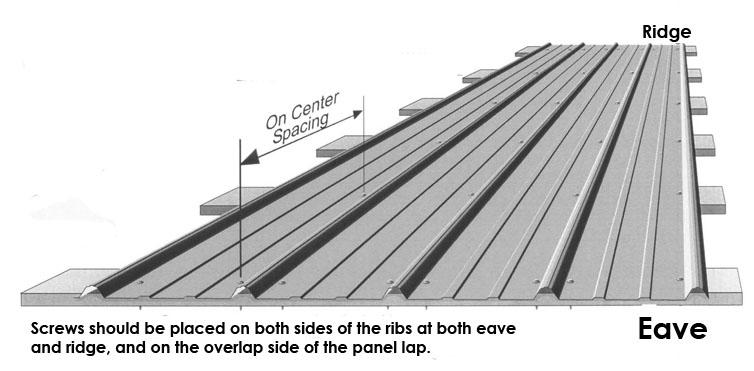

R panels provide for attachment to metal purlins a minimum of 12 x 1 hex head tek for 2 foot spacing between rows of screws multiply the total linear feet of metal times 1 9 retrieve content.

Kiln dried softwood is recommended for purlins or decking pine fir hemlock and spruce.

Screw line spacing for metal roofing over metal purlins.

Metal roofing gauge sizes.

When using purlins fabral recommends a maximum spacing of 24 on center note that 5v requires solid decking.

Pullout values decrease if the fasteners protrude completely through the purlins.

Purlins are non pressure treated 1 x 4 x 12 lumber that is installed on to the roof in a specific layout pattern and screw pattern.

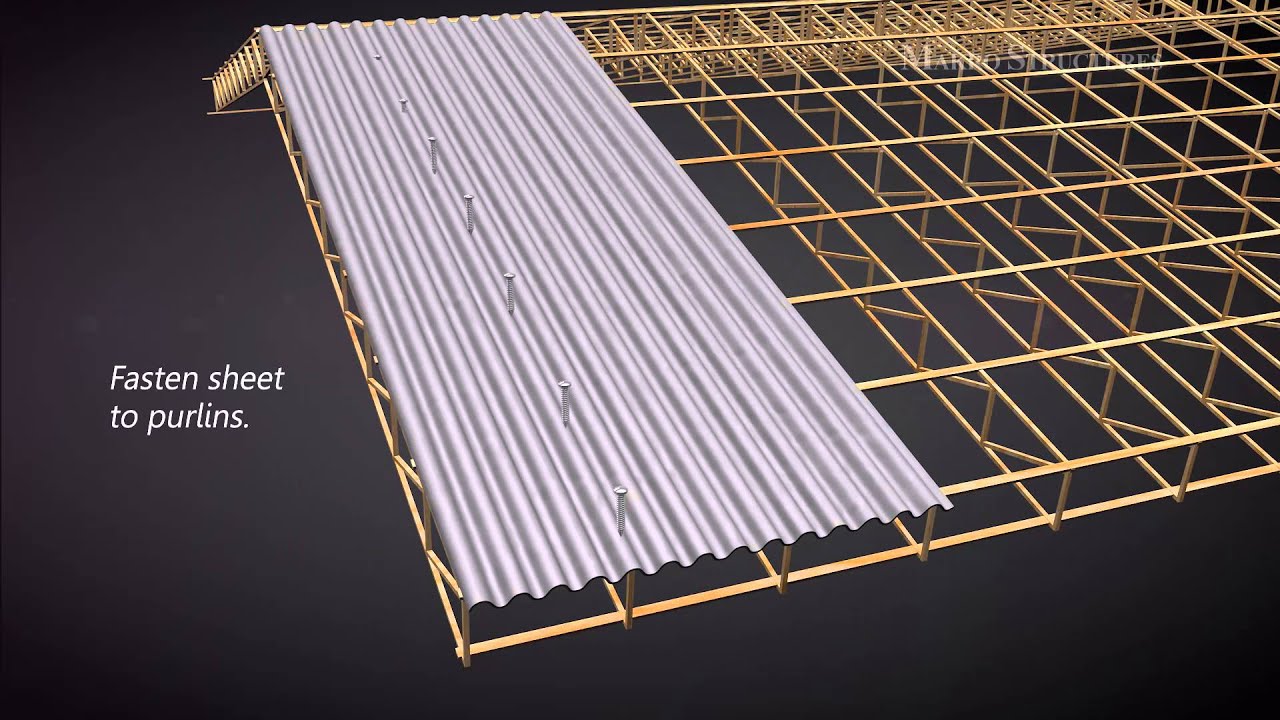

Once the purlin spacing is determined then the metal roofing panels are typically attached to every line of purlins.

Purlin spacing is dependent on profile of the metal and gauge plus snow and wind load plus what the rafters are designed to carry.

Fyi we run purlins on 3 5 feet on center depending on size of purlin.

R panel install manual metal roofing vinyl siding answer to the growing demand for metal roofing and siding needs.